With our wide range of capabilities, NSI produces a variety of products and assemblies. Complex components are designed and manufactured using the latest materials and manufacturing technologies on the market.

NSI continues to be at the forefront of the design and production of trailer hitch assemblies for the automotive market. NSI supplies hitches on multiple vehicle platforms, serving its customers’ needs from low volume service to high volume production.

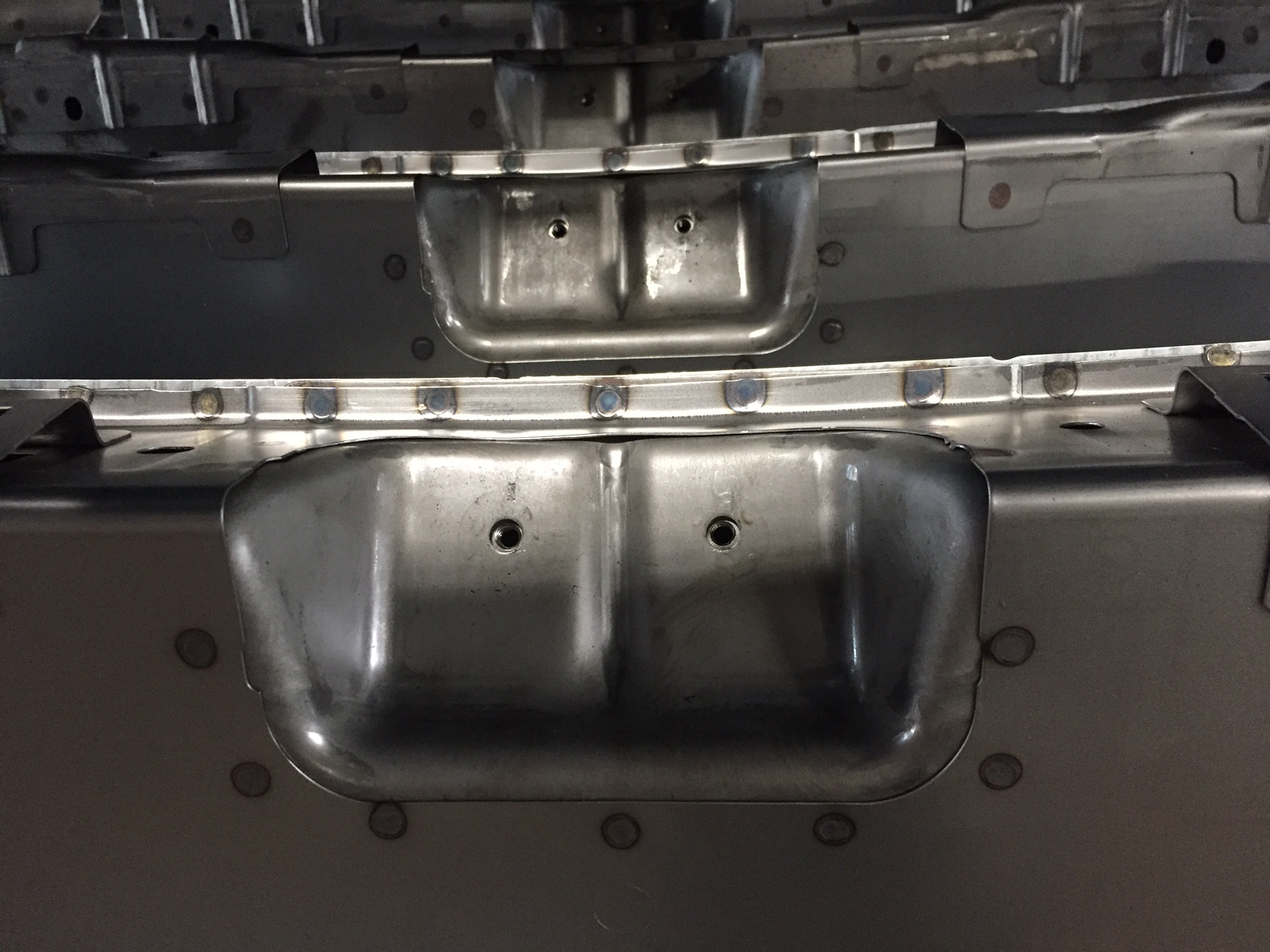

NSI has supplied cross members and torsion bar supports to the OEM market for over twenty years. Our engineers work with our customers to develop the most lightweight and cost effective designs for these structural assemblies. Processes involved in the production of these critical assemblies include the most state-of-the-art servo presses, fiber laser cutting, and robotic welding.

Engine Mounts isolate and reduce the vibration between engine and frame, one of the major discomforts caused to the driver. NSI uses FEA (Finite Element Analysis) to determine the correct engine mount stiffness to enhance the ride and driver comfort.

NSI provides full program management for suspension related parts. We leverage our relationships with strategic partners around the globe to deliver our customers the best parts at the lowest price.

From simple brackets to deep-drawn parts, NSI provides a variety of other stampings and welded assemblies.